How chemical regulations are hampering the EU’s Coronavirus response

This is probably going to be a controversial article, but I feel that someone has to point out what we have been discussing in the chemical industry ever since the implications of REACH became clear.

Although REACH has improved Safety Data Sheet and labelling information significantly through the publication of the REACH dossiers, it has also had a disastrous effect on the EU chemical industry. This malign effect has been magnified by the workings of the Biocidal Products Directive.

(By the way, I would expect other forms of EU-only chemical regulation have also had adverse effects on the chemical supply chain inside the EU, but these are the ones whose effects I am most aware of. If you know of other regulations which are affecting our response to an epidemic, please do email me with the information).

As a fellow scientist, engineer or person interested in chemical regulation, you’ll be expecting me to back up this assertion with evidence, and as a fellow nerd, I agree!

What is this malign effect REACH has had on the EU chemical industry?

There have been a number of malign effects, some which are clearly visible, and others which are hidden, unless you are an older participant in the chemical industry (like me).

The first bad effect of REACH is the visible one of a massive reduction in the number of chemicals freely available in the EU marketplace in any quantity you would like to purchase.

This can clearly be seen in ECHA’s own data. The total number of unique pre-registered chemicals is currently 145 297, although there will be some duplication within this number. If I recall, the figure in 2010 was around 110,000.

Admittedly, this included the whole EINECS list, which was registered in its entirety by 2 companies, both of whom were “spoken to severely” by ECHA.

You could argue that not every chemical was going to be registered for REACH, and that’s correct. But the estimates for the numbers of registrations were reduced significantly from the early days, as the sheer cost of REACH data became apparent.

The original numbers of registrations anticipated was around 30,000 to 40,000, if memory serves, yet to date only 22 877 individual substances have been registered. We are “light” on registrations, and that means fewer chemical substances on the EU market.

We have also seen the quantities of chemicals available being deliberately reduced to meet the REACH registration thresholds. Prior to REACH, there was no restriction on the quantity of most substances companies made or imported, but now the REACH thresholds, at 1 – 10 tonnes per annum, 10 – 100 tonnes, 100 – 1000 tonnes and above 1000 tonnes really do matter.

I will not go into the fine detail of why these chemicals have “gone missing”, but the main impact has been the cost of data (as required in the REACH regulation), which was greatly exacerbated by the EU’s insistence on registering the highest tonnage bands first. This meant that the highest data costs were shared by a few registrants, which made registration costs look very high, and put off a lot of potential registrants.

If the lowest tonnage band, which is the lowest data costs had been shared by a lot of people, the registration costs would have been much lower, and the shape of the industry would have been much more natural, with in-built resilience that a lot of manufacturers or importers brings.

Now we have a distorted supply chain for many chemicals, and a barrier putting off new entrants, because the cost of registering at 1 – 10 tonnes is higher than it could and should have been.

You may think that fewer chemicals on the marketplace is a good thing, because they are harmful, but that is a fallacy. We need hazardous chemicals to make beneficial ones, which are often beneficial because of those hazardous properties like flammability or toxicity; and often very hazardous chemicals are used in industry to make less hazardous beneficial ones.

And the problem is that we don’t know what the next wonder-drug or biocide is going to be, and therefore what it’s ingredients are. We may even find that a cure for coronavirus needs a chemical raw material which has been banned or restricted under REACH.

This is unhealthy for society. We should be focussing on ensuring the widest possible range of chemicals on the EU and UK marketplace, because we don’t know what we don’t know (the famous “unknown unknowns” of Donald Rumsfeld). And let the market react to crises, instead of needing the EU or member states to lift bans or permit extra importation or manufacture, as governments inevitably act much more slowly than businesses.

The second bad effect of REACH is a reduction in the number of chemical companies in existence. Evidence for this is harder to come by, but it is likely that smaller family companies with older owners will have retired rather than go through REACH.

But it’s not just about the numbers, it’s about the delicate interconnecting ecosystem which had built up over time in the UK and EU chemical industry. The chemical industry is not simple, it does not have straightforward supply chains.

Company X makes a chemical by reaction, Company Y formulates it into a consumer product and Company Z sells it is the exception rather than the rule. Company X may need several other companies to provide its raw materials, which may include formulations as well as substances. Company Y will need substances, and possibly formulations, for its raw materials from several other companies, who in turn may need multiple suppliers.

We don’t have supply chains in the chemical industry, we have supply webs, or supply networks. The final destination of most chemicals is not to the end user, the consumer – it’s actually supplying other industrial companies.

“The chemical industry itself is the largest single purchaser of chemical products.” Investopedia: https://www.investopedia.com/ask/answers/042015/what-types-industries-are-main-consumers-products-chemicals-sector.asp . “Industry is the biggest customer for EU chemicals“, CEFIC chemicals landscape 2020 https://www.chemlandscape.cefic.org/wp-content/uploads/combined/fullDoc.pdf

REACH has affected these delicate networks by reducing the number of products available, reducing the amounts available to purchase, and reducing the number of companies who supply these products.

The third bad effect of REACH is the massive amount of technical expertise it has hoovered up, removing experienced chemists from their true job of making chemicals as efficiently as possible. The worst impact of this has been to remove experienced people from new product development, whether this is in making and developing new chemicals and manufacturing processes, or developing new chemical formulations which are more stable, or more effective.

The reason why experience matters more than theory is because product development is as much about discovery of what will work, and how to make something work on a commercial scale, rather than design.

Anyone who thinks you can sit down and design (a) a new molecule, (b) a process to make that molecule and (c) an industrial process which will make the molecule efficiently and safely, and do all of this on paper, is clearly unaware of how the chemical industry works, and the many problems we encounter as we try to make chemical products.

Knowledge of how specific chemicals behave in different situations can only be obtained through testing, whether it’s running reactions to see whether you can make a substance, and then optimise the process in the lab into something which may be worthwhile taking further; and finally taking the lab process and scaling it up to a process which works safely on an industrial scale can take many man-hours and involve hundreds if not thousands of experiments and tests.

We have had a dozen years of stalled product development throughout the UK and EU, due to the distraction of coping with REACH. Many companies are trading on their historic product range, rather than developing new products.

This means that, as older people retire, chemical companies have less in-house experience in product development, everything from R&D through to scale up, to engineering chemical processes in-house (which is the exception rather than the rule in the UK these days, most companies outsource their chemical engineering for design and build, which means that there is less in-house engineering knowledge).

This matters for an individual business, because new products are the lifeblood of any manufacturing business in the long term, and it also matters for society as a whole, because if companies are not used to developing new products, they will make more mistakes, and not be as quick and confident if they are suddenly asked to make new products to help the country cope with a crisis.

We can already see this in the manufacturing sector, where companies making medical devices have been asked by the UK Government to help make more ventilators, and it is possible that chemical companies may be asked to help make hand sanitiser, cleaning products and drug precursors.

How does it affect our response to Coronavirus?

As well as the points we’ve already discussed, REACH acts as a massive brake on businesses in the chemical sector.

To quote the ECHA website: “Companies must register substances that they manufacture or import in quantities of more than one tonne per year in the EU/EEA before they start these activities, unless the substances are exempt from registration.“

So if we suddenly need to make hand cleanser in massive quantities to meet demand, companies who are new to this area can only bring in 1 tonne per annum legally of each raw material, and companies who already make hand cleanser ingredients are limited to making as much as their REACH registration will allow; and if they import any raw materials, they are similarly limited by the REACH registration they hold.

Instead of hundreds of individuals deciding to respond to the increase in demand by satisfying it, the natural working of the marketplace is impeded.

And this situation also applies to pharmaceuticals (whether this is medicine or vaccines). Their raw materials all need to go through REACH before the human health regulations apply to the finished product in its finished state for consumers.

Similarly, biocides also have an extra layer of regulation to contend with, which has suddenly become very important in the coronavirus epidemic because of the need to sanitise hands and surfaces to slow the spread of the virus.

Why does the Biocidal Products Regulation (BPR) make matters worse?

BPR brings in an extra requirement that all biocides, and products making biocidal claims, must be registered separately to REACH.

In the case of our hand cleanser, if we want to say it’s biocidal, we need to have a BPR registration for it as a biocidal product, as well as making it from REACH registered substances.

The list of permitted biocides is held at ECHA, and set by the European Commission. Yes, you heard it right, a bunch of unelected politicians and civil servants decide which biocides should be available in the EU.

And the last time I heard an estimate for the costs for registering a biocidal product, it was around 1 million euros (because of the test data, consultancy fees etc). Even if it were 100,000 euros, this is enough to put off most manufacturers or formulators making small quantities, because you need a large volume of sales to make registration worthwhile.

As you would expect, this extra layer of bureacracy and cost has greatly reduced the number of biocides and biocidal products on the market, which matters hugely because of the tendency for pathogens to resist toxins over time, meaning that biocide formulations need to be changed to counteract this.

The effect of BPR has been to reduce our capabilities to deal with pathogens and microbial resistance, and to reduce our speed of response significantly.

In the current crisis, this matters more than ever.

What can be done about this during the crisis?

There isn’t a great deal which we in the chemical industry can do at the moment apart from responding to demand within the terms of our REACH registrations and BPR registrations, unless we are given permission to manufacture more products outside these rules by the UK (or other Member State) Government.

Germany has already started this process, with a derogation on 4th March to allow the manufacture of hand sanitisers containing 2-propanol, see https://www.knoell.com/en/news/derogation-hand-disinfectants-germany .

It remains to be seen if the UK Government will bring in any derogations to enable companies to manufacture hand sanitisers or biocidal cleaning products, or any relevant drug precursors outside the scope of REACH and BPR, and if they do this whether it will be done in time to help the general public.

What should we do about this for the longer term?

Within the UK, we have a unique opportunity to reframe UK-REACH (and other chemical regulations) because of Brexit.

We should keep the benefits of much better information to inform our Safety Data Sheets, while reducing or ending the market interference which EU-REACH has given us.

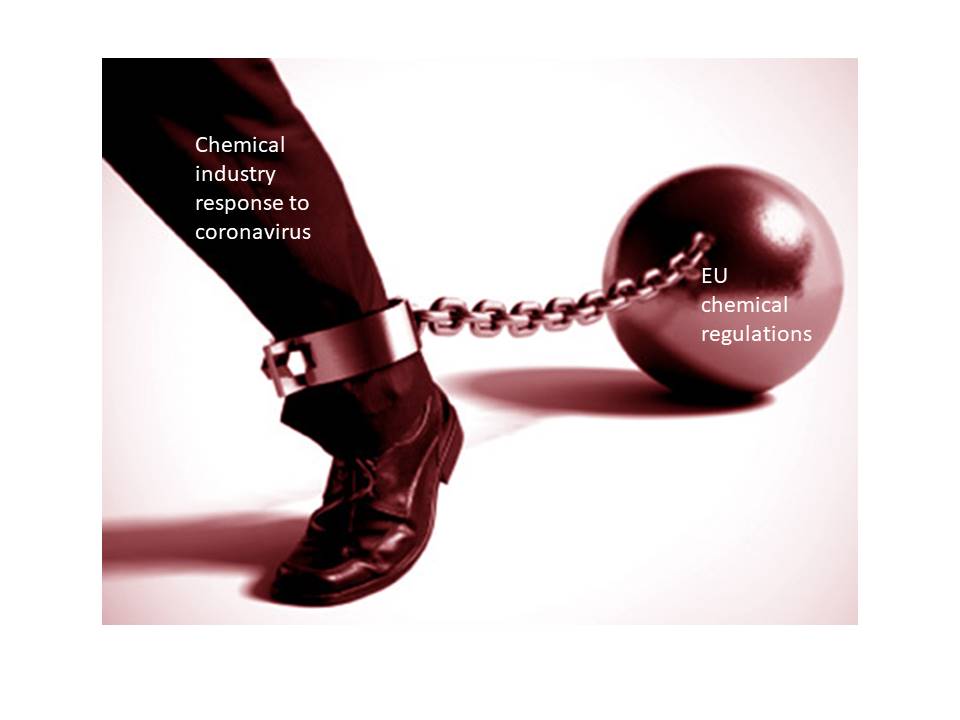

Our aim should be a healthy, flexible and responsive chemical industry eco-system, as we had prior to REACH, and which is still mainly in business, albeit trading in handcuffs due to the effects of REACH.

In my opinion, this can, and should, be done without compromising human safety and health, or environmental protection.

But that’s a topic for another article.

Hope this is useful, and that you, your family, and your colleagues stay well during the coronavirus crisis.

GHS Classification Courses from TT Environmental Ltd

16th March 2020

Like this article? You’ll love our free guide to CLP (and you’ll also get our articles delivered direct to your inbox every week!)